YOUR WATER,

OUR RESPONSIBILITY

Wherever Water Flows,

Data Flows

Every water system in a building tells a story—about efficiency, asset health, safety, and risk. Maestro 360 captures that story in real time.

Commercial water management is a complex, multi-disciplinary challenge—one that overburdened facility teams and traditional, reactive water treaters aren’t built to solve alone. From central plants to point-of-use systems, Maestro 360 monitors and manages water wherever it flows, transforming continuous system data into actionable insight that protects assets, reduces operating costs, and mitigates life-safety risk.

By pairing industry-leading specialists with real-time monitoring, analytics, and AI, Maestro 360 models every chemical adjustment, temperature shift, and pressure change as it happens. This allows us to identify the precise balance point where systems operate efficiently, corrosion and failure risks are controlled, and safety is maintained—before small issues escalate into downtime, compliance exposure, or costly repairs.

-

Potable water is the baseline water that enters your building—and with it, the risk you inherit from the municipal supply. Maestro 360 provides continuous visibility into domestic water quality from the point of entry through distribution, helping facilities understand, manage, and mitigate life-safety risk, support water management plans, and reduce exposure to waterborne pathogens such as Legionella.

-

From labs and central sterile processing to manufacturing and specialized equipment, process water quality directly impacts outcomes. Maestro 360 delivers real-time monitoring and documentation to ensure consistency, reliability, and compliance.

-

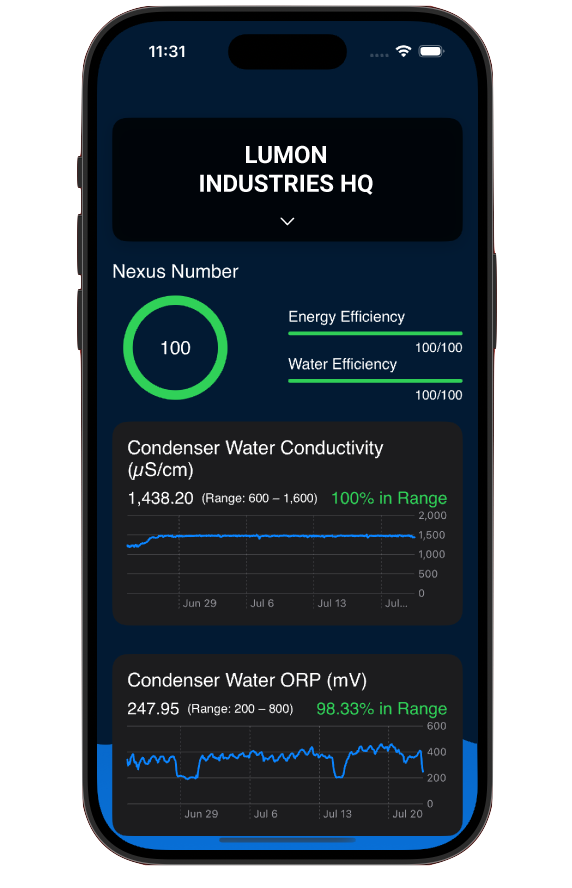

Cooling towers are one of the largest consumers of water and energy in a facility—and one of the highest-risk assets. Maestro 360 continuously monitors condenser water chemistry, cycles of concentration, and operating conditions to reduce blowdown, improve heat transfer, and protect cooling towers and chillers from corrosion, scale, and biofouling.

-

Poor boiler water quality accelerates corrosion, reduces efficiency, and increases unplanned downtime. We monitor boiler and steam systems to optimize chemistry control, protect critical equipment, and support safe, reliable steam generation for heating, sterilization, and process loads.

-

Chilled water loops are essential to HVAC performance and occupant comfort. Maestro 360 provides visibility into chilled water quality and system health, helping prevent fouling, corrosion, and efficiency loss that can silently drive up energy costs.

-

Cogeneration systems demand tight water quality control to protect heat exchangers and maximize uptime. Our real-time monitoring and analytics help facilities maintain stable operation while safeguarding high-value equipment.

-

Alternative water systems introduce new operational and compliance challenges. We monitor grey water and reclaimed water systems to ensure proper treatment performance, reduce risk, and support sustainability initiatives without compromising safety.

-

Many facilities rely on dedicated cooling loops for mission-critical equipment, including IT, electrical, or process loads. Maestro 360 monitors these systems to ensure consistent performance and protect high-value assets from water-related failure.

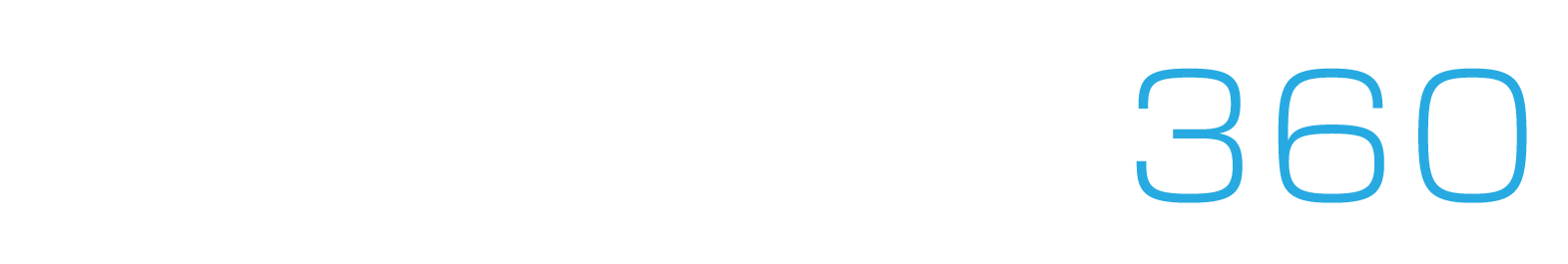

REAL-TIME DATA COLLECTION

Maestro 360 uses purpose-built, on-site hardware panels and sensors installed at key points across your water systems to continuously measure water quality and chemistry—including pH, conductivity, ORP, temperature, corrosion rates for copper and mild steel, and treatment chemistry levels. This is how we capture real-time data—down to every second—and securely push it to our cloud platform, Symphony, for continuous visibility and analysis.

Expert Ownership, Always-On Visibility

Entrust water management to dedicated experts with real-time visibility, control, and human oversight—not periodic check-ins.

Turn Water Into an OpEx Advantage

Uncover hidden energy and water savings to offset rising operational costs and reduce surprise repairs or remediations.

Less Manual Work, More Automation

Automate repetitive water system oversight, maintain chemistry levels, and receive instant alerts when KPIs drift out of range.

Compliance & Risk, Covered 24/7

Maintain continuous potable water compliance and stay ahead of water-borne pathogen risks like Legionella with round-the-clock monitoring.

PROTECT CRITICAL CAPITAL ASSETS

Extend the life of cooling towers, chillers, and boilers by preventing corrosion, scaling, and unplanned failures.

ENTERPRISE-WIDE INSIGHT

Instantly view performance across all your facilities with a centralized dashboard to benchmark, spot trends, and drive strategic decisions.

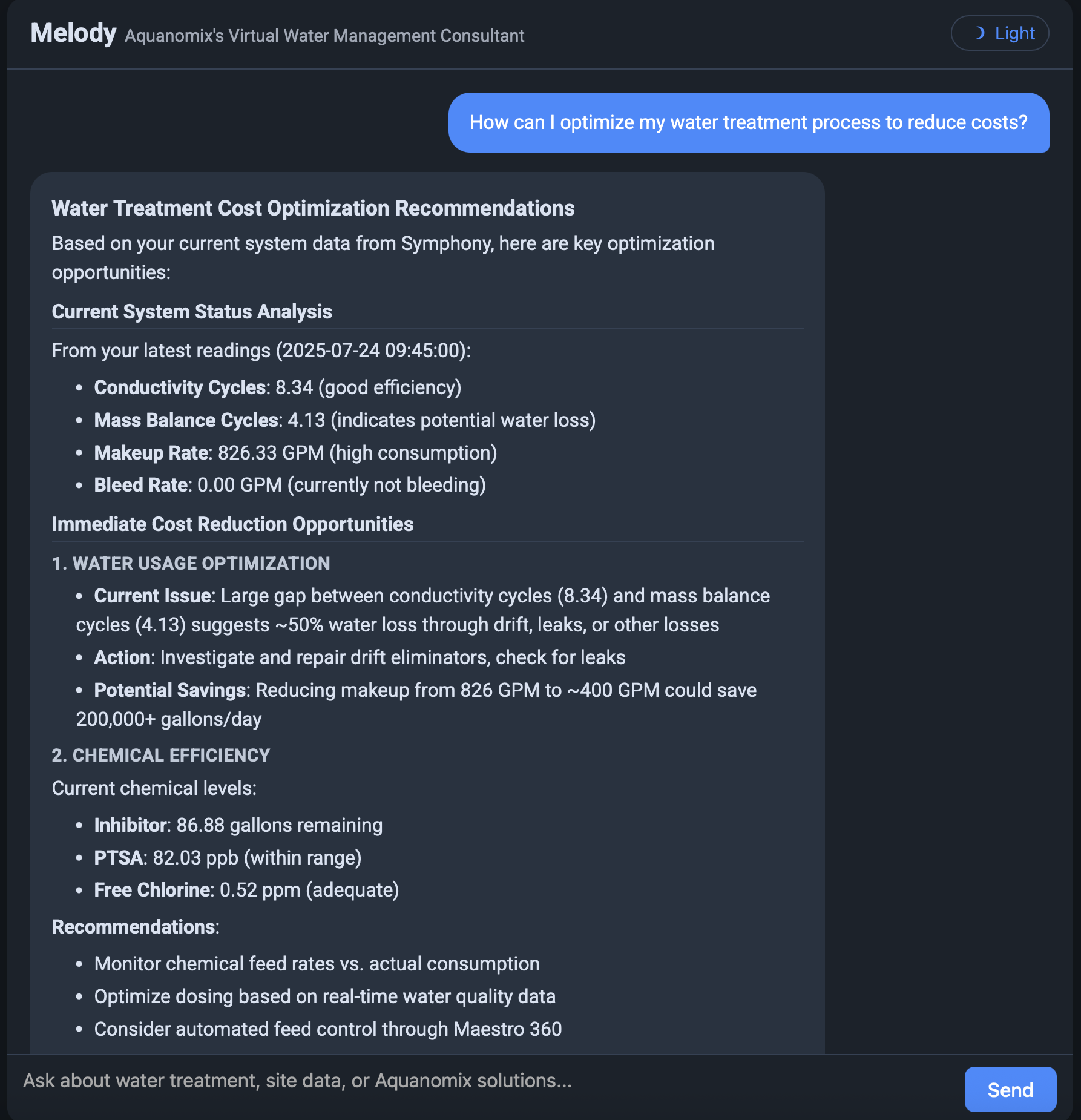

Your always‑on AI water expert, trained on the best treatment expertise and powered by your live facility data to deliver instant, tailored answers and actionable insights.

EFFICIENCY &

OPEX REDUCTION

In condenser systems, scaling and biofilm act like insulation, slashing heat transfer efficiency. Maestro 360 controls water chemistry in real time to optimize blowdown, keeping surfaces clean, cutting energy waste, reducing water use, and even lowering cooling tower cleanings. These efficiency gains often make Maestro 360 a cost‑positive solution.

Maestro 360

Designed for your workflow

Whether you want more visibility and performance from your current water treater or to save time and delegate your water safety responsibilities, Maestro 360 adapts to your needs, transforming reactive to proactive.

ESSENTIAL

Bridge the Gap Between Your Water Treater and Real Results

Most Popular

PLUS

Unlock Measurable OpEx Savings and Proactive Legionella Protection

MAX

Your Water, Our Responsibility—Complete Management & Risk Protection